Media

Work Gallery

Innovation in Pump Manufacturing

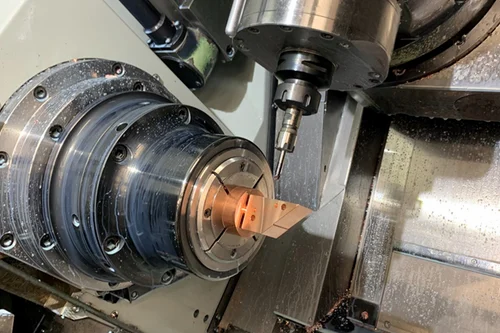

At Flowguards, we are committed to the belief that exceptional products emerge from a foundation of precision, innovation, and unwavering dedication. Our state-of-the-art manufacturing facility features advanced CNC machines, Vertical Machining Centers, and high-precision tools, allowing us to produce top-tier pump components with unparalleled accuracy. Each phase of production, from raw material processing to final machining, is executed with meticulous care by our experienced team. The accompanying images illustrate our cutting-edge infrastructure and the skilled craftsmanship involved in creating Vertical Inline High-Pressure Pumps and premium spare parts. By maintaining a strict policy of 100% in-house production, we guarantee consistency, reliability, and superior quality in every product we offer.

At Flowguards, every pump and spare part undergoes strict quality testing and inspections. This ensures that as Flowguards manufactures Vertical Inline High-Pressure Pumps, each product meets the highest standards of performance, safety, and durability.

At Flowguards, we leverage advanced CNC and VMC operations to achieve precision machining for critical components. This high-tech process ensures superior accuracy, durability, and consistency in every partsupporting our expertise as Flowguards manufactures Vertical Inline High-Pressure Pumps trusted across industries.

At Flowguards, we specialize in the manufacturing of high-quality stainless steel (SS 304/316) parts that ensure strength, durability, and corrosion resistance. Our in-house facilities and precision machining processes guarantee components that meet international standards supporting our commitment as Flowguards manufactures Vertical Inline High-Pressure Pumps with unmatched reliability.