Why Choose Flowguards

Vertical Inline Pumps – Reliable & Efficient

At Flowguards, our Vertical Inline Pumps are designed for efficiency, durability, and space-saving performance. With a compact inline design, they connect easily to pipelines, reduce installation costs, and simplify maintenance.

Industries like water treatment, HVAC, power generation, oil & gas, and manufacturing trust these pumps for their steady flow, low noise, and long service life. As a reliable manufacturer, Flowguards delivers pumps that improve productivity, save energy, and ensure dependable performance for industrial needs.

Contact Now

Get in touch with our pump experts today

Key Advantages of Flowguards Vertical Inline Pumps

Lower Installation and Maintenance Costs

Compact design eliminates costly foundations and simplifies access, enabling faster service operations and reduced downtime

Versatile Pump Types

Options include multistage pumps for high-pressure applications, as well as rigidly or flexible coupled configurations tailored to your operational needs

Energy Savings with Frequency Converters

Inline pumps paired with variable frequency drives (VFDs) offer responsive speed control, reduced energy usage, and extended component lifespan

Superior Energy Performance

Advanced hydraulics and full-size impellers—without trimming—can boost efficiency by up to 5% and capacity by 10%

Applications of Vertical Inline High Pressure Pumps

In reverse osmosis and desalination processes, water must be forced through semi-permeable membranes at very high pressure. Vertical inline multistage pumps provide the necessary constant feed pressure, ensuring efficient salt and contaminant removal. Their stainless-steel construction makes them resistant to corrosion, even in saline or brackish water environments.

For municipal and industrial water treatment, these pumps maintain steady flow and pressure for filtration, ultra-filtration, and chemical dosing systems. Their reliability in continuous operation ensures uninterrupted treatment processes and high-quality purified water output.

Boilers in power plants, process industries, and heating systems require a continuous supply of high-pressure, high-temperature water. Vertical inline high pressure pumps are ideal for boiler feed as they can handle hot fluids, provide stable flow, and withstand demanding thermal conditions.

Safety-critical environments like residential complexes, commercial buildings, factories, and warehouses rely on firefighting pumps to deliver water at high pressure during emergencies. Vertical inline pumps are compact, quick-starting, and capable of maintaining constant pressure, making them a preferred choice in fire protection systems.

Key Features

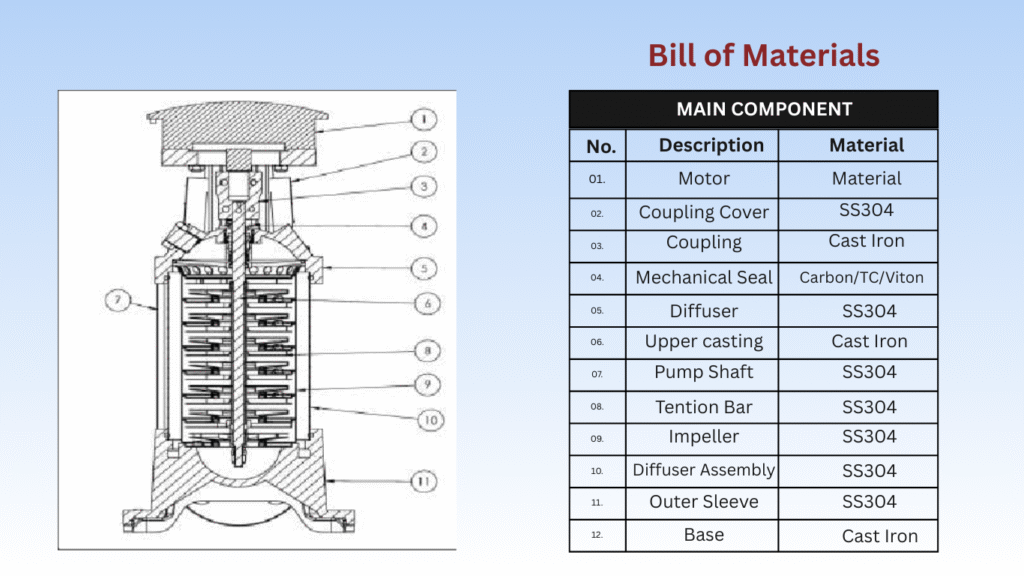

Vertical inline high pressure pumps operate on the centrifugal principle. The liquid enters the pump axially, is accelerated by high-speed rotating impellers, and discharged radially through diffusers. In multistage models, the fluid passes through several impellers in sequence, with each stage adding pressure.

- Stainless Steel / Cast Iron Materials – Ensures strength, durability, and corrosion resistance.

- High Efficiency – Optimized hydraulic design reduces energy consumption.

- Low Noise & Vibration – Suitable for indoor and commercial use.

- Easy Maintenance – Modular design allows quick servicing and replacement of parts.

- Continuous Duty Operation – Built for 24/7 performance in demanding environments.

Applications Across Industries

Water Treatment

Boiler Feed & Industrial Utilities

Oil, Gas & Power

RO Water Plants

HVAC & Cooling

Applications Across Industries

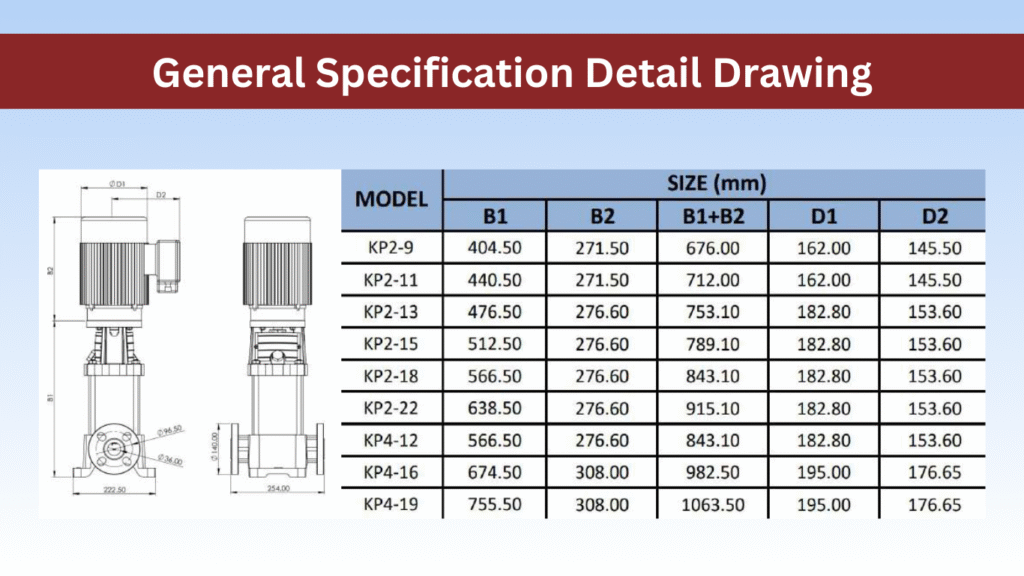

Pump Specification:-